Infrastructure

- At present Kiran Technocast Pvt. Ltd.have 3 production lines, well equipped with foundry and modern machineries and equipments. Our advanced production technology utilizing latest machineries, equipments and manufacturing process produces and maintains international quality standards of S.G.Iron Casting set by Engine & Vehicle manufacturers and International Quality control institutes.

-

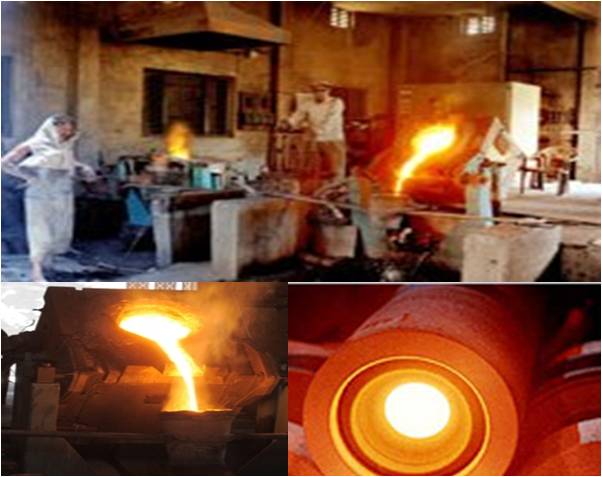

Foundry Division

Foundry

division is equipped with 1 Induction furnaces having melting

capacity of 10 MT per day

and 3 Apollo Furnaces. In addition to furnaces, casting testing

equipments and metal testing laboratory is equipped in foundry

where raw material tested before casting for its chemical

properties, Hardness, and Wet analysis.

Casting of Cylinder liners and Cylinder Sleeves is done in grey

cast iron of G-4000 Grade. In such a way so as to achieve

prelatic structure free from ferrite and graphite (max up

to 2-3%). They are casted by centrifugal casting process

so as to achieve compact structure and high strength as well as

desired wear resistance, hardness and tensile strength. Each and

every batch of casting is tested at the time of pouring as well

as afterward completely in the in-house laboratory to maintain

chemical composition, mechanical properties and metallographic of

the end products so as to meet the exact requirement of

metallurgical norms. These casting of cylinder liners are

further machined in our well equipped machinery plant having

latest special purpose machines, CNC turning center and

hydraulically operated honing machines to achieve plateau honing

configuration.

- Quality control

Kiran Technocast Pvt. Ltd. is equipped with the following Quality check

instruments for its consistent and high quality cylinder liners

and sleeves :

•

Spectrometer

• Material Analysis lab installed with Spectrometer

• Compound Optical Microscope

• Micrometer

•

WELCOME

WELCOME